Coffee 101: The Humble Coffee Bean

Coffee is a fruit. The coffee plant is an evergreen shrub with fruit that resembles a cherry in shape and color. There are normally two seeds in each cherry, which are in fact the green coffee beans. It takes about five years for a coffee tree to begin producing fruit.

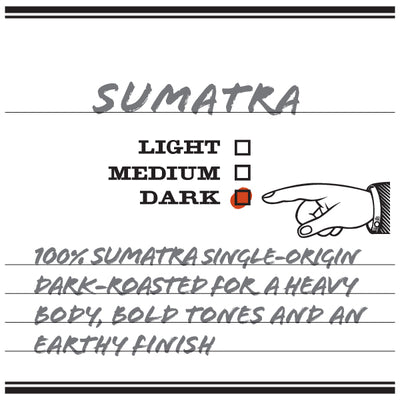

Coffee is a tropical plant and growing regions are located along or near the equator. Coffee plants are grown all over the world. Here at Verena Street, we carry several different origins of coffee, including Washed Brazil, Natural Brazil, Sumatra, Honduras, China, El Salvador, Colombia, Vietnam, Kenya and Peru.

Only perfectly ripe cherries are selectively picked and typically the trees must be re-picked three to six times to harvest all the fruit. Harvesting is the most expensive step of processing coffee due to the intensive labor required. Not only is coffee grown in several different regions around the world, but there’s also different types of coffee.

Arabica Coffee

About 60-70% of the world’s coffee production is Arabica coffee. Arabica coffee is grown at higher altitudes, and the coffee plants and beans take longer to mature. When purchasing coffee, you’ll notice that Arabica coffee is more expensive. It’s very popular in high quality, specialty markets. All Arabica coffees are hand picked and only the highest quality Arabica beans are used in our Verena Street coffees.

Robusta Coffee

About 30-40% of the world’s coffee production is Robusta coffee. Robusta coffee is grown at much lower altitudes, and the coffee plants and beans mature much faster than Arabica. These beans are cheaper and very popular in lower quality, commercial markets.

From Cherry to Green Bean: The Harvest Process

Did you know that coffee plants actually grow fruit called coffee cherries? Now you do! Coffee plants grow cherries that contain 1-2 seeds per cherry. The seeds are green (or unroasted) coffee beans. Coffee cherries are picked once ripe.

After the harvest, coffee beans must be separated from the other layers of the coffee cherry by either the wet or dry processing method. The wet method is more expensive, however it is the process used almost exclusively on higher quality Arabica coffees like those used for our Verena Street coffees.

The wet method uses water to remove stones and dirt from cherries. Flesh of the fruit is removed with a de-pulping machine, then they are fermented. The beans are then washed and dried in the sun on concrete patios.

The beans are then sorted (by bean size, density, and color) and unwanted objects such as sticks, stones, and damaged beans are removed. Once sorted, the beans are graded on a scale based on the number of imperfections, age of the beans, and cup flavor characteristics. The high quality specialty grade Arabica beans used in our coffees are the top 2% of all Arabica beans.

The Roasting Process

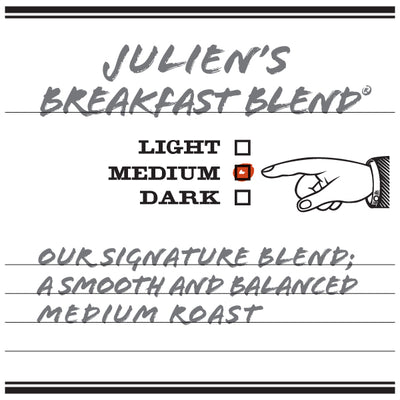

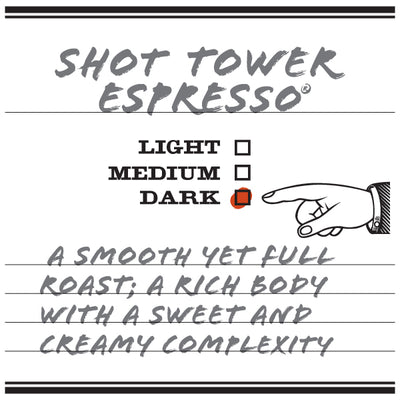

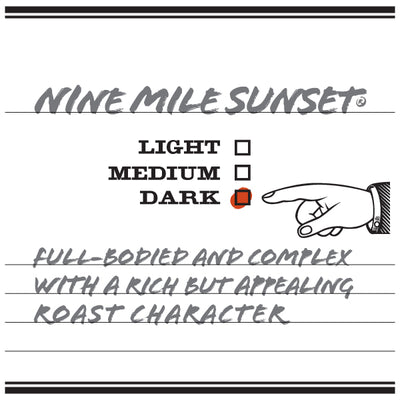

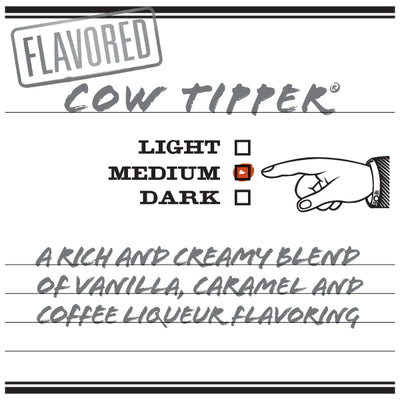

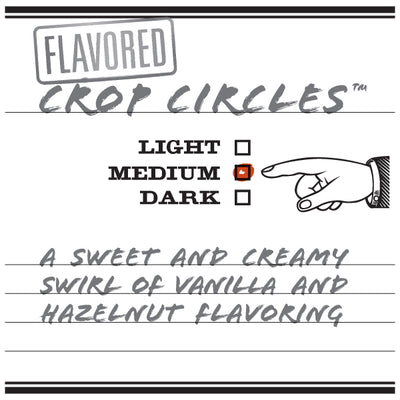

Once the green beans arrive at our facility, it's time to roast the coffee. Roasting coffee beans to perfection is an art as much as a science. When we roast coffee beans, it develops the beans’ flavor and aroma. Beans are roasted at different times and temperatures, resulting in light, medium, and dark roast blends.

Light roasts are roasted for the shortest amount of time and have the most caffeine. Dark roasts are roasted for the longest amount of time and have the least caffeine. While roasting, the beans will “crack” at about 385 degrees. This “crack” is used to measure how long after the first crack until they reach each roast level. When they crack, the natural oils inside the beans come out and give the coffee its natural flavor. Yum! Different types of coffee require different roasts to bring out their richest flavor.

- The first stage involves raising bean temperature to between 200 and 250F. The beans begin to lose moisture and change color to a pale yellow.

- When beans reach an internal temperature of 400F volatile oils are released that give coffee its distinctive flavor and aroma.

- Moisture is drawn out and the bean cells expand and break open, producing a crackling or snapping sound.

- The sugars caramelize, causing the beans to darken. Oils begin to appear on the bean's surface.

- Roast times range from 90 seconds to 35 minutes, depending on roasting equipment and degree of roast.

- Ending temperature ranges from 410 to 480F.

- Coffee is cooled by air cooling and water quenching that stops the roasting process.

Did you know? Light roasts are roasted for the shortest amount of time and have the most caffeine. Dark roasts are roasted for the longest amount of time and have the least caffeine.

Did you know? Light roasts are roasted for the shortest amount of time and have the most caffeine. Dark roasts are roasted for the longest amount of time and have the least caffeine.

The Grind

Beans that are not kept in whole bean format for packaging must be ground. Grinding the bean multiplies the bean's surface area and prepares the beans to release their flavor in the brewing process.

Grinding has the most affect on the flavor of the coffee. Choosing the correct grind is critical for optimal flavor extraction. Grinding can be done at the roasting plant (as many Verena Street coffees are), in a retail store, coffee house or even at home before brewing.

Packaging the Coffee

Proper packaging of coffee is the best defense against two of its natural enemies - air and moisture. Before packaging, coffee must also be degassed. Coffee beans release carbon dioxide for six to ten hours after roasting. If coffee is packaged and sealed before all the gases have escaped, the gases will be released inside the container.

After degassing, the beans are packaged in one-way valve bags. These one-way valve bags allow the carbon dioxide to escape through the valve without letting air or oxygen back in.

Certifications

Besides beans varying in origins, they can also have different certifications.

Rainforest Alliance Certified Farms

- We proudly believe in fairness, sustainability, and responsible sourcing

- The Rainforest Alliance:

- Focuses on social, environmental, & economical sustainability

- Works to conserve biodiversity

- Promotes the rights and well-being of workers, their families, and communities

- Learn more here!

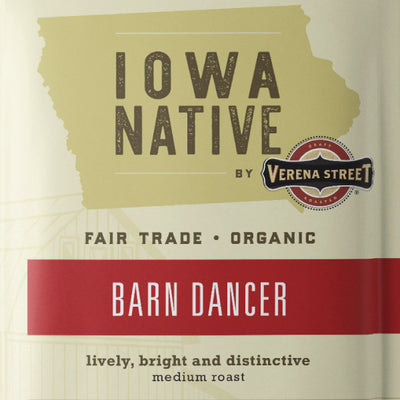

Fair Trade Certified™

- Designed to overcome poverty

- Empower producers in the poorest countries

- Give producers a guaranteed price for their products

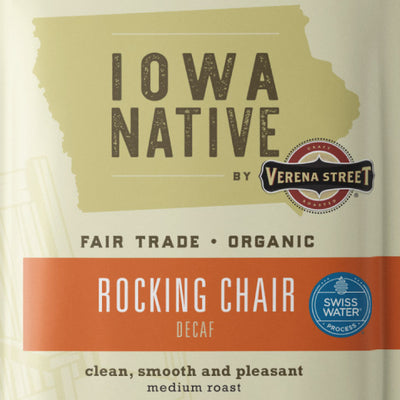

- Iowa Native line is fair trade and organic

- Learn more here!

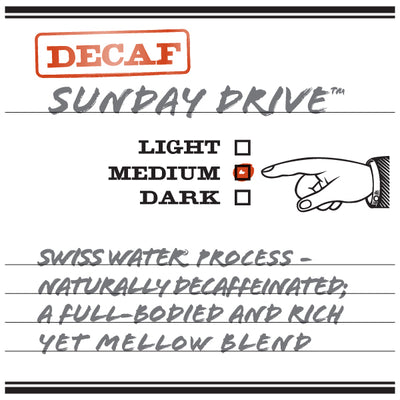

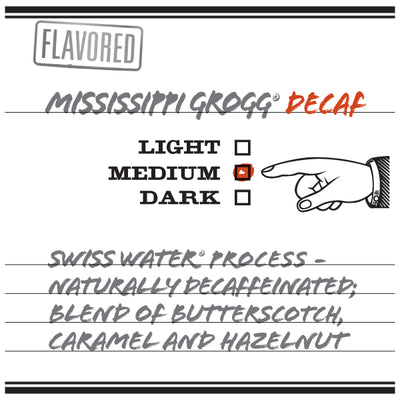

Swiss Water® Process

- Our beans undergo a natural decaffeination process

- Provides full-bodied flavor without chemicals

- The Process:

- Green beans are soaked & create water that’s charged with flavor and caffeine

- Those beans are then discarded

- The caffeine is then filtered out of the water using carbon filters

- Caffeine-free, flavored water is now the decaffeinating tool

- Batches of green beans are soaked in this water which creates flavorful, decaf coffee

- Learn more here!

And the Rest is History

- You buy your favorite blend of Verena Street coffee online or in your nearest grocery store.

- You brew your coffee using your preferred grind and brewing method.

- You put that delicious brew into your belly!

- And....repeat.

Next time you’re brewing your favorite Verena Street blend, take a moment to appreciate the exciting journey your coffee beans went on to end up in your cup!

FAQs About How Coffee Is Made

How is coffee made from bean to cup?

Coffee starts as a fruit that grows on tropical shrubs. The cherries are picked when ripe, and the seeds inside are processed, dried, and sorted. Those green coffee beans are then roasted, ground (or left whole), and brewed into the coffee you drink. Every step affects the flavor, freshness, and quality in your cup.

What part of the coffee plant is used to make coffee?

The seeds inside the coffee cherry are what we roast and brew as coffee. Each cherry contains one to two seeds, which are processed into green coffee beans. After roasting, those beans become the familiar coffee we grind and brew each day.

What is the difference between Arabica and Robusta coffee beans?

Arabica beans grow at higher altitudes and take longer to mature, resulting in smoother, more flavorful coffee. Robusta beans grow faster at lower altitudes and taste more bitter. We use only 100% Arabica beans at Verena Street to ensure rich, balanced flavor in every cup.

What happens during the coffee roasting process?

Roasting transforms green coffee beans by heating them to high temperatures. Moisture evaporates, sugars caramelize, and natural oils are released. This process gives coffee its aroma and flavor. Roast levels—from light to dark—are controlled by temperature and time to bring out the best in each bean.

Does grinding coffee affect the flavor?

Yes. Grinding affects how quickly water extracts flavor during brewing. A finer grind brews faster and stronger, while a coarser grind takes longer and is smoother. The right grind size depends on your brewing method. We offer both ground and whole bean coffee so you can brew it your way.

Stay Connected

Want more blog content? Click here.

Connect with us on social media! We love hearing from you. Follow us on Instagram and like us on Facebook to stay up to date on all things Verena Street. Leave a like, comment, or share our posts with your friends and family. We appreciate your support!

1 comment

Lois

Do you use chemicals to take the caffeine out of your decaf coffee or is done using a chemical procedure? I can’t seem to find that info on anything.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.