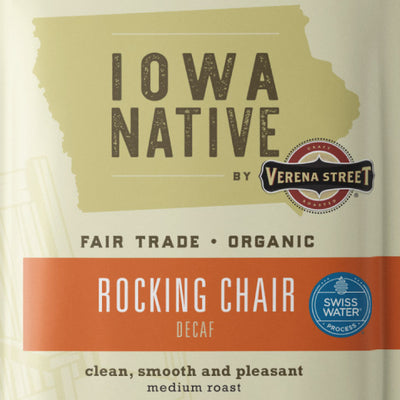

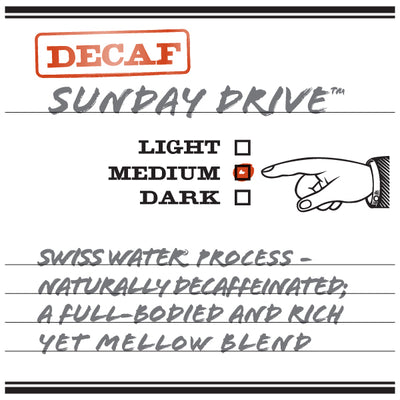

We have been asked numerous times what our decaffeination process is for our decaf blend, Sunday Drive™.

The simple answer to that question: Swiss Water Decaffeination Process.

While not a simple decaffeination process, it does provide us with beans that we trust to provide the best quality for our customers that enjoy our decaf blend.

If you were wondering what this process entails, allow me to explain all the ways that coffee can be decaffeinated.

Swiss Water Decaffeination Process

A Little History First:

- Founded in Switzerland in 1933 as a chemical-free water decaffeination process.

- Developed as a commercial method by Coffex S.A in 1980.

- The Swiss Water Process was introduced to the market in 1988 by a company based in Canada.

As mentioned above, this process of decaffeination does not use chemicals of any kind to remove the caffeine from the coffee beans. It relies instead on entirely two things: solubility and osmosis. This process creates a coffee bean that is 99.9% caffeine-free.

- It starts with soaking a batch of green coffee beans in hot water to dissolve the caffeine.

- The water is removed from the beans and passed through an activated charcoal filter which only allows the capture of the caffeine molecules. The important oil and flavor molecules get to stay in the water.

- This water is kept in a tank and the original beans are thrown away. This flavorful caffeine-free water is reused to remove caffeine from a new batch of green beans.

- The process starts again with the soaking of this new batch of beans in the caffeine-free flavorful water only allowing the dissolving of the caffeine in the beans while not losing all the important flavors.

- This method of decaffeination is mostly used with organic coffee beans.

Mountain Water Process

A similar process to the Swiss Water Process, except they use clear, pure water from the glaciers of Mexico's Pico de Orizaba mountain. The founding company, Descamex, is based in Veracruz, Mexico. The company patented its process in 1989 and became certified as organic in 2003. This process also produces 99.9% decaffeinated coffee beans.

Direct Solvent-Based Process

- A batch of green beans is steamed for about 30 minutes in order to open their pores.

- Next, the beans are repeatedly rinsed with either methylene chloride or ethyl acetate for about 10 hours to remove the caffeine.

- The solvent is drained away and the beans are steamed again to remove any leftover chemicals.

Specialty Coffee is part of a remarkable network of coffee growers, producers, exporters, roasters, baristas, and coffee lovers. We play one unique and special role in that chain. We remove caffeine and that's all. Once our job is done, the beans are ready to ship out to coffee importers and roasters all over the world. In our small way we’re helping to bring Specialty Coffee to more homes for people to drink, enjoy, and share any time of day. Our process also ensures coffee certifications remain intact. - Swiss Water

Indirect Solvent-Based Process

- A batch of green beans is soaked in very hot water for several hours to dissolve the caffeine as well as all the important oils and flavors.

- That water is removed to another tank while the beans are washed repeatedly with either methylene chloride or ethyl acetate for about 10 hours.

- The bean-solvent mixture is heated again to dissolve any remaining caffeine and solvent.

- The saved water is reintroduced to the beans in order for them to reabsorb the oils and flavors.

CO2 Process (Carbon Dioxide Process)

- A batch of green beans is soaked in water and placed in a stainless steel tank.

- The tank is sealed and liquid CO2 is forced into the coffee to remove the caffeine from the beans at about 1000 psi.

- The liquid carbon dioxide acts to dissolve the caffeine while leaving the flavors and oils behind.

- The caffeine-rich CO2 is drained and transferred to another container where it's returned to its gaseous state, leaving the caffeine behind. The CO2 is then reused.

So, there you have it. All the different ways that coffee is decaffeinated. Typically, if a coffee is not labeled as having a certain decaffeination process it has usually been treated with either the direct or indirect-solvent based process. It's always a safe bet to ask the coffee company what it uses for their process. Especially if you are concerned with chemicals and the caffeine content left behind.

Swiss Water® Process uses the elements of water, temperature and time to create some of the most intriguing decaf coffee. - Swiss Water

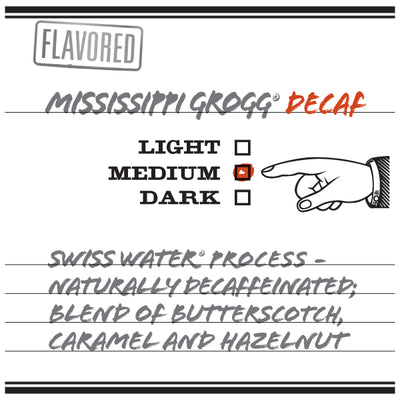

We know you care about where your coffee comes from. The folks at Verena Street® care about our customers and the quality of the coffee we are giving you.

Shop our full range of coffee naturally decaffeinated by the Swiss Water® Process.

Related Posts:

3 comments

Maureen McCarthy

Love your coffee! Nine Mile Sunset is my favorite coffee ever! My dr. recently recommended I cut-out caffeine. During warm weather i was willing to give- up my daily pot of french press “Sunset” but these cool mornings call for warm beverages.

Unfortunately, I’m not finding much variety inyour decaf offerings. Is it possible to have a dark roast decaf? Any chance that you might expand your decaf line? My fingers are crossed!

Allison brown

Your coffee is the best! We are coffee snobs. We have had many many types from all over the world. Keep rocking it. Thank you for your excelence!!!?

Linda Hoffma

Is your water processed decaf coffee less acidic than ordinary decaf?

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.